Specialized digital solutions quietly power modern life, combining processing power, memory, and input/output functions to execute dedicated tasks. Unlike general-purpose devices like laptops, these tailored computing units operate within larger mechanical or electronic frameworks. Industry reports indicate over 98% of microprocessors power specialized digital solutions rather than traditional computers.

These integrated platforms appear in everyday items from smart thermostats to automotive control modules. Their optimized design focuses on reliability and efficiency, often operating unnoticed while managing critical functions. A microwave’s timing mechanism and factory robots’ motion controls both rely on this invisible technological backbone.

Three key features define these systems: task-specific programming, real-time operation capabilities, and minimized resource consumption. Engineers prioritize seamless hardware-software integration to meet exact performance requirements. This approach enables consistent operation in environments where standard computers would struggle.

Key Takeaways

- Specialized computing units perform dedicated functions within larger devices

- Over 98% of microprocessors operate in integrated digital solutions

- Optimized for reliability, efficiency, and real-time performance

- Found in household appliances, vehicles, and industrial equipment

- Require minimal resources compared to general-purpose computers

Introduction to Embedded Computer Systems

From your morning coffee maker to city traffic lights, unseen computational forces drive modern conveniences. These specialized units combine hardware and software to perform precise operations within larger mechanisms.

Overview of Embedded Computing

Purpose-built digital cores power everything from fitness trackers to aircraft navigation. Unlike multipurpose computers, they execute predefined tasks with maximum efficiency. A microwave’s timer and a car’s anti-lock brakes both rely on this targeted approach.

Developers optimize these solutions for specific environments. Some handle basic operations using single chips, while advanced versions manage complex networks in medical equipment. This adaptability makes them vital across industries.

Significance in Modern Technology

Smart cities and automated factories demonstrate embedded computing’s transformative power. These systems enable real-time data processing in traffic management grids and energy-efficient buildings.

Over 80% of industrial machinery now uses self-regulating components powered by this technology. From wearable health monitors to automated irrigation, they form the backbone of connected ecosystems. Their role in advancing IoT innovations continues to reshape how we interact with the physical world.

Understanding the Core Concepts of Embedded Systems

Behind every smart device lies a focused computational core designed for efficiency. These solutions prioritize exact functionality over adaptability, creating purpose-built architectures that power essential operations.

Defining Dedicated Processing Units

Task-specific engineering forms the foundation of these units. Developers optimize hardware-software bundles for singular objectives like temperature regulation or motion control. Unlike multipurpose devices, they operate with predetermined parameters and minimal user interaction.

Resource efficiency drives their design. Many utilize stripped-down operating systems or firmware, eliminating unnecessary features. This approach enables reliable performance in constrained environments – from medical implants to automotive safety mechanisms.

Contrasting with Versatile Computing Platforms

General-purpose devices prioritize flexibility through upgradable components and diverse software support. Embedded alternatives focus on deterministic outcomes, executing programmed instructions with near-zero latency. Consider these key distinctions:

| Feature | Dedicated Systems | Multi-Use Devices |

|---|---|---|

| Primary Function | Single predefined operation | Multiple applications |

| Hardware Complexity | Minimal components | Expandable resources |

| User Interaction | Limited interface | Graphical interfaces |

Industrial robots exemplify this specialization. Their control modules process sensor data in microseconds – a capability standard computers can’t match without excessive power consumption. This targeted design philosophy ensures optimal performance where it matters most.

History and Evolution of Embedded Systems

The journey of specialized computing began with groundbreaking aerospace innovations that reshaped technological boundaries. Pioneering engineers transformed theoretical concepts into practical tools, creating architectures that balanced precision with resource constraints.

The Apollo Guidance Computer and Early Milestones

NASA’s lunar missions catalyzed critical advancements in compact processing. The Apollo Guidance Computer (1965) weighed 70 pounds – revolutionary for its time – using monolithic integrated circuits to achieve unprecedented reliability. Charles Stark Draper’s team at MIT engineered this marvel to process navigation data with 2KB memory, proving specialized architectures could thrive in extreme environments.

Military applications accelerated development. The Autonetics D-17 (1961) guided Minuteman missiles using discrete transistors, demonstrating real-time processing capabilities. These early implementations established fundamental design principles still relevant today: fault tolerance, deterministic operation, and minimal power consumption.

Advancements Leading to Modern Embedded Solutions

Silicon breakthroughs transformed possibilities. Federico Faggin’s Intel 4004 (1971) – the first single-chip microprocessor – enabled mass production of efficient processing units. MOS technology allowed manufacturers to integrate memory, logic circuits, and I/O controls onto single substrates.

| Era | Technology | Impact |

|---|---|---|

| 1960s | Discrete Components | Military/aerospace specialization |

| 1970s | Microprocessors | Consumer electronics emergence |

| 2000s | System-on-Chip | IoT and smart device proliferation |

Modern solutions leverage nanometer-scale fabrication, supporting complex operations from autonomous vehicles to medical implants. This progression from room-sized units to microscopic chips illustrates six decades of relentless optimization.

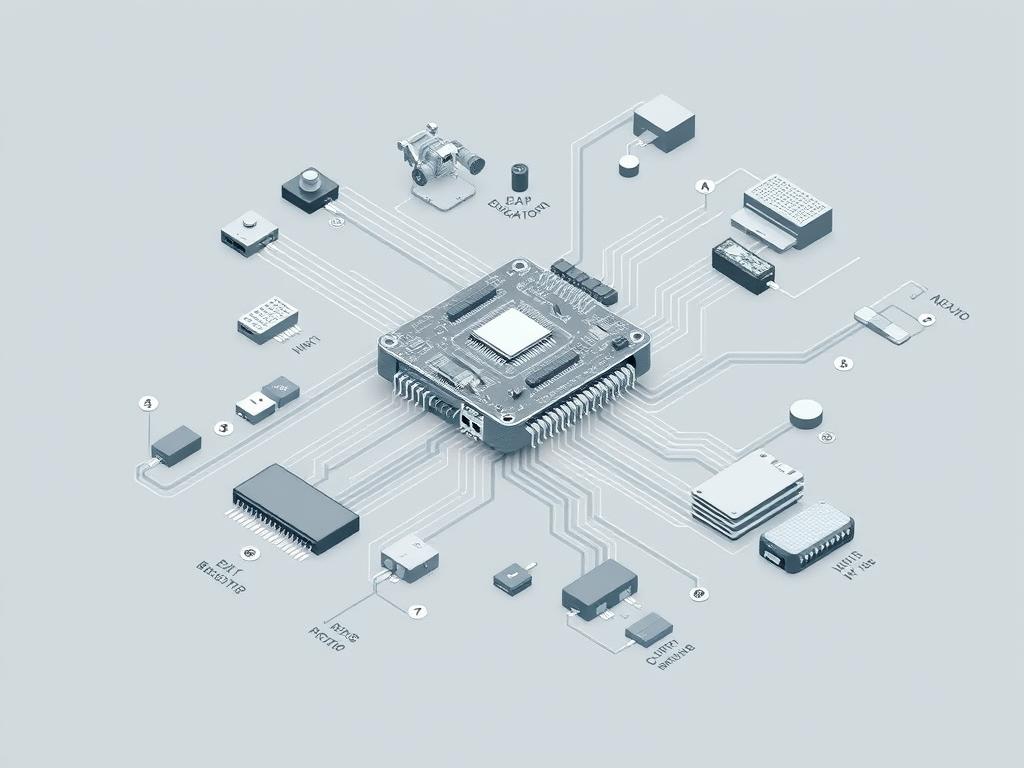

Key Hardware and Software Components

Modern technology relies on specialized frameworks that combine physical parts and coded instructions. These architectures balance computational power with energy efficiency to meet strict operational demands.

Core Hardware Elements

Three primary elements form the backbone of these solutions. The central processing unit executes commands using clock speeds ranging from 8 MHz to 1 GHz. Memory modules store temporary data and permanent instructions, while input/output ports connect sensors and actuators.

| Component | Types | Key Function |

|---|---|---|

| Processor | Microcontrollers, DSPs | Execute programmed tasks |

| Memory | Flash, EEPROM, SRAM | Store code and runtime data |

| I/O Interfaces | UART, SPI, GPIO | Connect external devices |

Essential Software Considerations

Developers use low-level languages to optimize performance in constrained environments. C remains the dominant choice, with 78% of professionals using it for firmware development according to IEEE surveys.

Real-time operating systems manage tasks with microsecond precision. Power management features extend battery life in portable devices. Error-checking protocols ensure stable operation across temperature extremes.

“Efficient code minimizes memory leaks while maximizing processing throughput – this balance defines successful implementations.”

How Embedded Systems Work: From Input to Output

Precision-driven mechanisms form the operational backbone of modern devices. These architectures convert environmental signals into actionable responses through streamlined workflows.

The Role of Sensors and Actuators in Data Processing

Sensor arrays act as digital nervous systems. Thermocouples measure temperature fluctuations, while accelerometers track motion patterns. These components transform physical phenomena into electrical signals for analysis.

Actuators execute decisions made by processing units. Electric motors adjust valve positions in HVAC systems. LED displays update based on user commands. This continuous feedback loop enables autonomous adjustments without human intervention.

Real-Time Operation and Communication Protocols

Time-sensitive applications demand microsecond responses. Anti-lock brakes analyze wheel rotation 100 times per second. Medical ventilators synchronize with patient breathing cycles using deterministic scheduling.

| Protocol | Speed | Common Use |

|---|---|---|

| CAN Bus | 1 Mbps | Vehicle networks |

| SPI | 10+ Mbps | Sensor arrays |

| Modbus | 19.2 Kbps | Industrial controls |

Communication standards ensure seamless coordination between components. Error-checking algorithms maintain data integrity during transmission. This synchronized approach allows multiple subsystems to work together reliably under strict timing constraints.

Real-World Applications of Embedded Systems

Invisible technological marvels power countless innovations across modern industries. These dedicated processors enable smarter functionality while remaining hidden from casual observation.

Consumer Electronics and Smart Devices

Modern homes showcase advanced integration of specialized processors. Refrigerators track expiration dates using internal sensors. Washing machines auto-adjust cycles through load detection.

Mobile technology thrives on compact architectures. Fitness trackers monitor heart rates using low-power chipsets. Smart speakers process voice commands through optimized neural networks.

| Device Type | Key Function | Power Usage |

|---|---|---|

| Smart Thermostats | Climate regulation | 1-3 Watts |

| Wireless Earbuds | Audio processing | 5-10mW |

| 4K Streaming Devices | Video decoding | 4-6 Watts |

Automotive, Healthcare, and Industrial Automation

Modern vehicles contain over 100 dedicated processors. Anti-lock brakes analyze wheel speed 100 times per second. Infotainment systems deliver lag-free navigation through optimized GPUs.

Medical advancements rely on precision architectures. MRI machines use real-time imaging processors. Insulin pumps maintain dosage accuracy through microsecond calculations.

Manufacturing plants demonstrate industrial-scale implementations. Robotic arms follow millimeter-precise movements. Quality control systems inspect 500+ items per minute using vision processors.

Exploring “what are embedded computer systems” in Practice

Hidden technological workhorses drive countless innovations through targeted functionality. These solutions balance precision with resource constraints, delivering reliable performance across industries.

Modern implementations range from single-chip controllers to multi-processor networks. Their architecture prioritizes mission-specific operations over general adaptability, ensuring optimal results in defined parameters.

Dedicated Functions in Everyday Devices

Smart home gadgets demonstrate focused applications. Programmable coffee makers use temperature sensors for perfect brewing. Fitness trackers analyze movement patterns through low-energy processors.

Industrial applications demand rugged reliability. Assembly line robots perform repetitive tasks with millimeter accuracy. These implementations highlight how purpose-built designs outperform generic alternatives.

The Impact on Efficiency and Performance

Energy optimization separates specialized units from standard computers. Traffic light controllers process data using 90% less power than desktop CPUs. Medical implants achieve decade-long battery life through ultra-efficient architectures.

Real-time responsiveness enables critical operations. Elevator safety mechanisms react within milliseconds. Aircraft navigation systems process multiple inputs simultaneously. This combination of efficiency and precision powers modern technological ecosystems.